Production

Customised production

Lalmek has since its inception in the 70s been an assertive driving force within hydraulic technology. We have tested the waters, built up a bank of knowledge and developed our own solutions, own components, own production methods and in many instances our own machines. Today, we have unique technical expertise at our disposal. Thanks to our customised production we can offer our customers a comprehensive solution consisting of hydraulics, mechanical designs and electrical control systems.

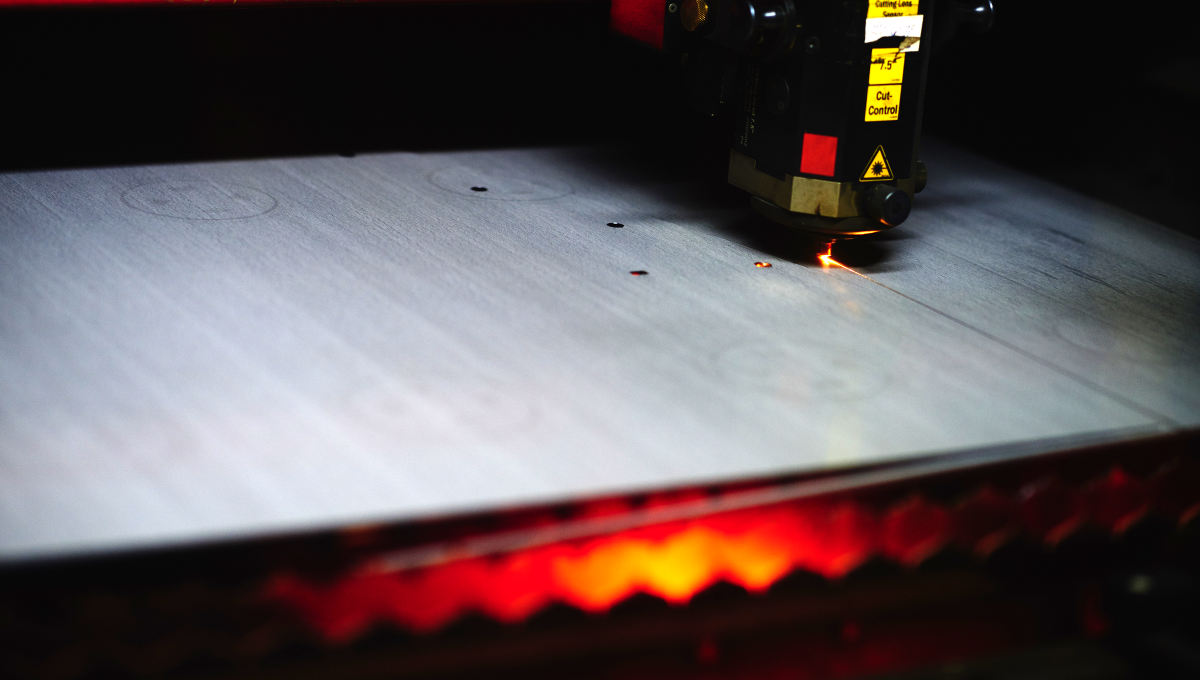

Laser cutting

Metal plate parts are cut quickly and efficiently with great precision using modern laser technology.

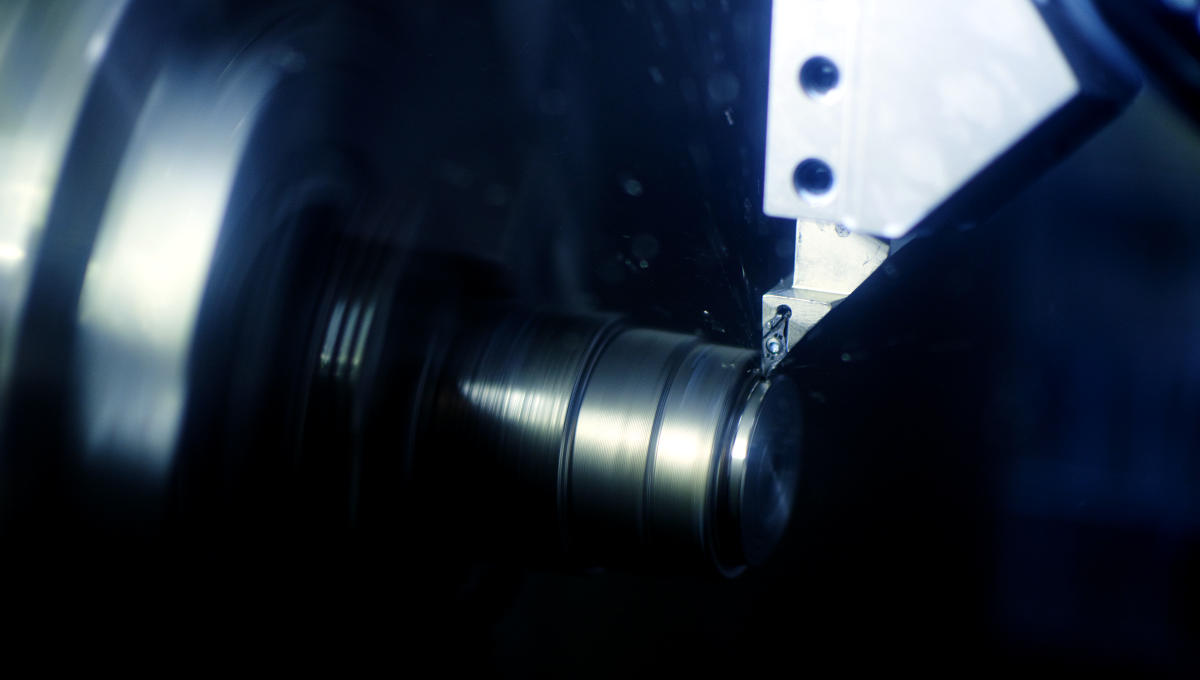

Machine processing

Lalmek Hydraulics has a number of multi-operation machines and CNC controlled lathes.

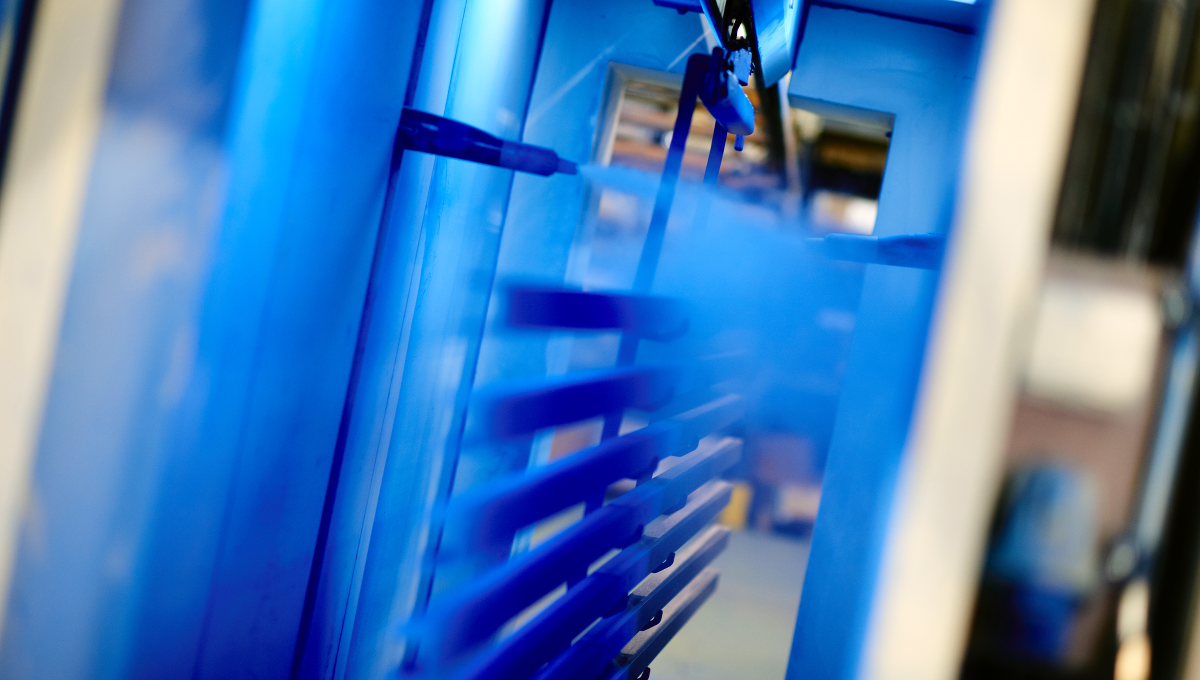

Brake press operations

Two modern CNC controlled brake presses form the laser cut metal parts with great accuracy.

Welding

At Lalmek Hydraulics machine components made of stainless as well as traditional structural steel are welded.

Final inspection

Components manufactured at Lalmek Hydraulics undergo final inspection after assembly.

Assembly

The assembly of hydraulic components and systems places high demands on accuracy , precision and hygiene.

Powder coating

We surface treat metal parts with electrostatic power coating to give good corrosion protection.

Wet painting

As a complement to power coating, Lalmek Hydraulics also wet paints components that require this.

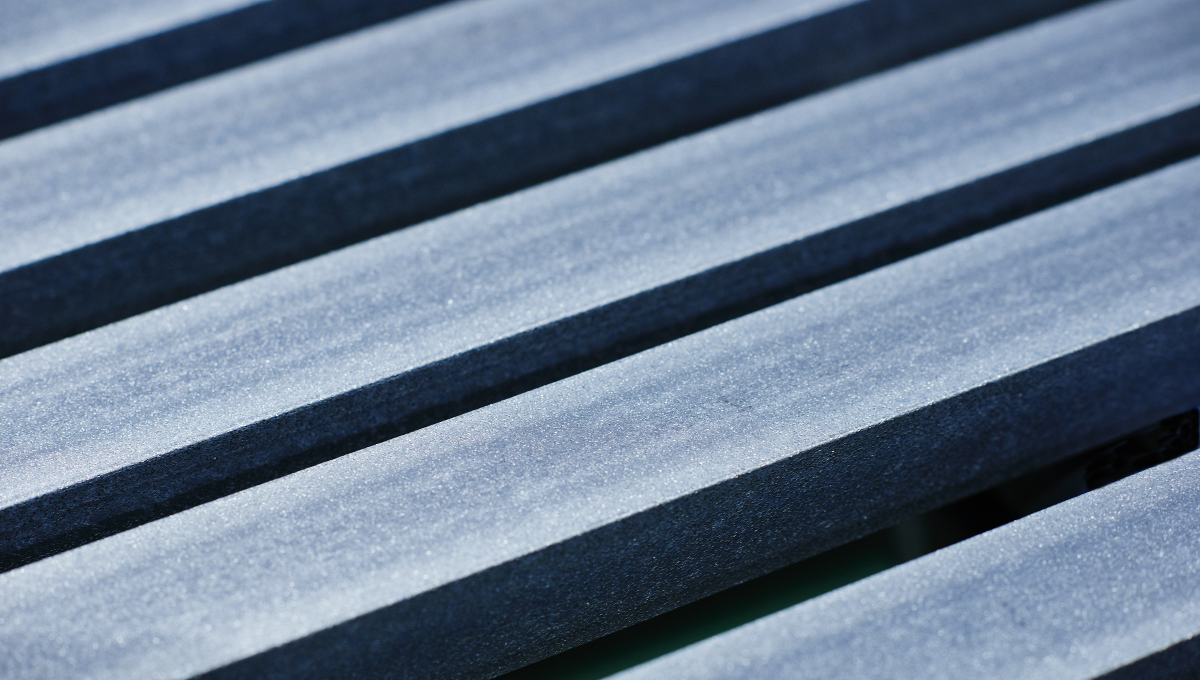

Steel blasting

In order to achieve the best possible paint adhesion, powder coating is preceded by steel blasting.

Electrical design

We design and program electrical control systems based on customer demands and the requirements of the hydraulics.